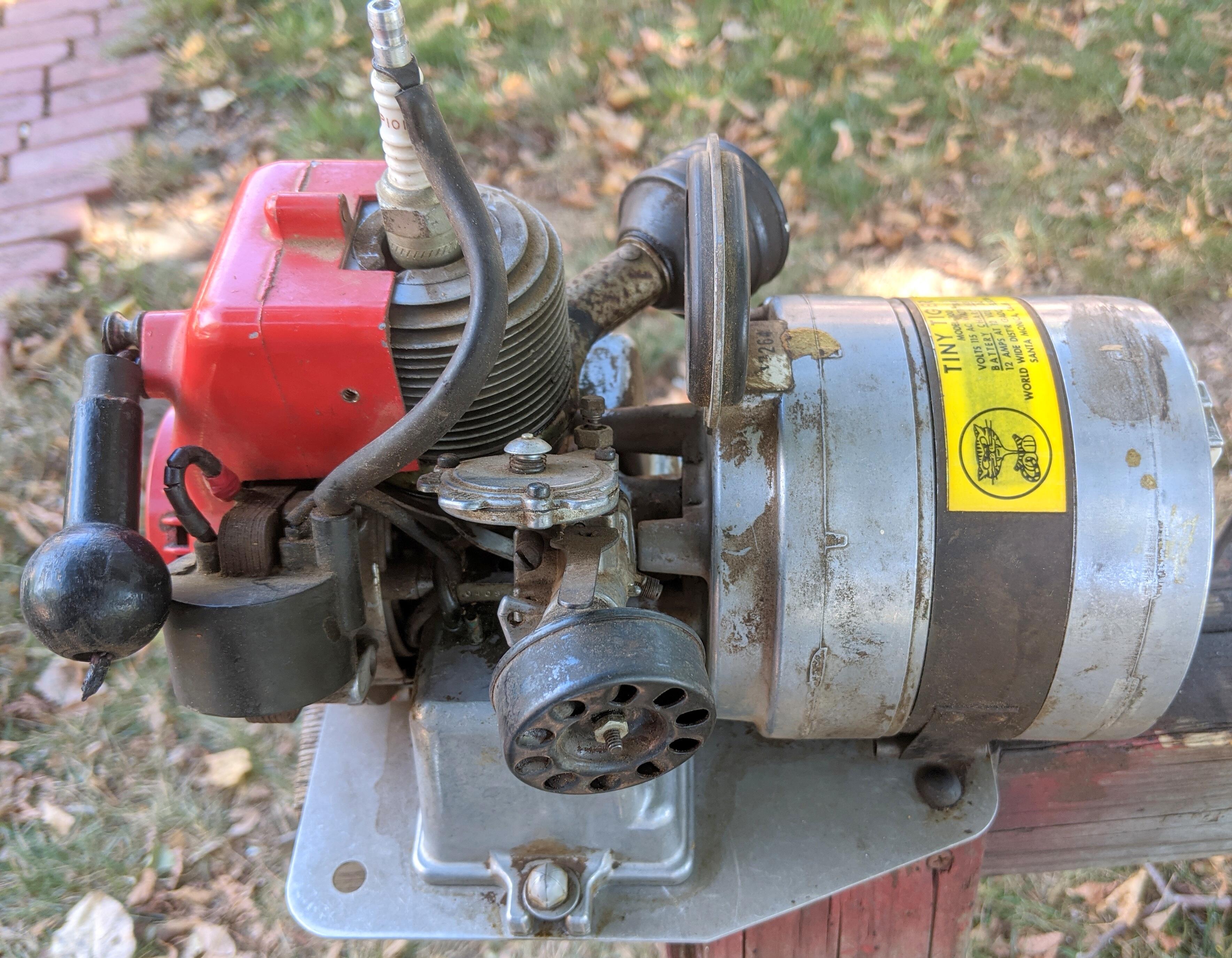

I took the flywheel off to clean the points. When I reinstalled the flywheel I was tightening the nut with about a 6" long combination wrench. Suddenly it didn't feel like it was tightening anymore or like something was yielding. I didn't know the torque spec but was nowhere near 90 inch lbs. Anyway I fired it up and it ran fine for a minute or so while I measured voltage and frequency and then the engine quit. I noticed the flywheel had slipped and sheared the aluminum key. After making the new key I reinstalled it and used my torque wrench, this time set to 90 inch lbs, and the stud broke at about 70 inch lbs. Examining the break, from the color I could tell it had been partially broken long before I got the generator. Since then I have drilled and threaded the crank for a stud. The crank seems to be hardened and is difficult to drill but I got sufficient depth to install the threaded stud. Tomorrow I'll probably try reinstalling the flywheel and running it again.

.thumb.jpg.e6f93209b94437b27667b72169814243.jpg)